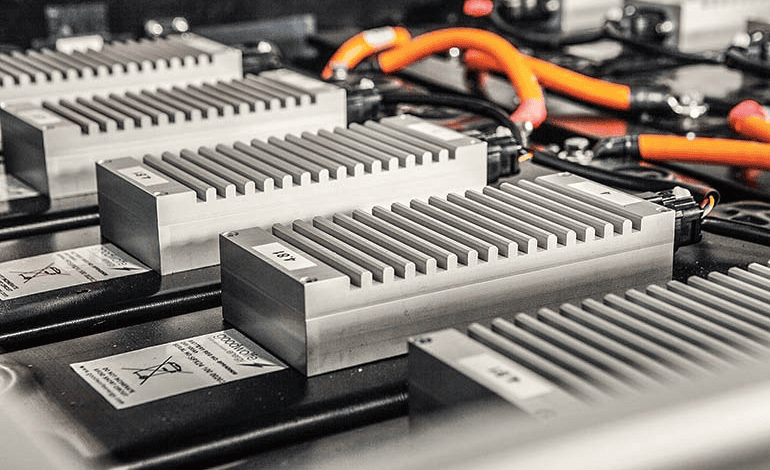

eMobility / Li-ion Batteries

At SPG, packaging for eMobility components, especially Lithium-Ion Batteries, is driven by stringent safety regulations due to their hazardous nature. All Lithium-Ion Battery packaging must pass stringent testing and comply with hazardous materials (Hazmat) classifications, which dictate specific packing instructions depending on the type of transport.

SPG’s packaging solutions include robust outer containers constructed from plywood, fiberboard or even steel and/or aluminum for larger packs, to provide impact resistance.

Internally, cushioning materials such as custom-molded foams, anti-static bubble wrap, and corrugated inserts provide crucial for shock absorption and to prevent movement or contact between terminals.

Key eMobility and Li-ion packaging considerations include:

- Impact Resistance: Battery packs must be designed to withstand significant impacts during normal operation, accidents, and transportation. This often involves outer casings made from metal, wood, or solid plastic.

- Vibration Dampening: Packaging needs to secure individual cells and modules to prevent movement and vibration, which can lead to damage and short circuits. Non-combustible, non-flammable cushioning materials are often used.

- Short Circuit Prevention: Each battery or cell must be entirely enclosed and protected against short circuits, preventing contact with other equipment or conductive materials.

- Enclosure Integrity: The battery pack enclosure must protect against ingress of dust and water, maintaining the integrity of the internal components.

Ready to learn about SPG’s custom-engineered eMobility the solutions?