Inner Packaging

Inner packaging (sometimes referred to as dunnage), is a vital part of the shipping process. Without it, there are few ways to ensure that shipments will be protected from harm during transit.

Inner packaging is an SPG specialty. We understand the delicate balance between design intricacy and cost effectiveness. Our design engineers work with clients to find the right balance between protection and cost for unique shipping needs. Below are some of SPG’s inner packaging solutions:

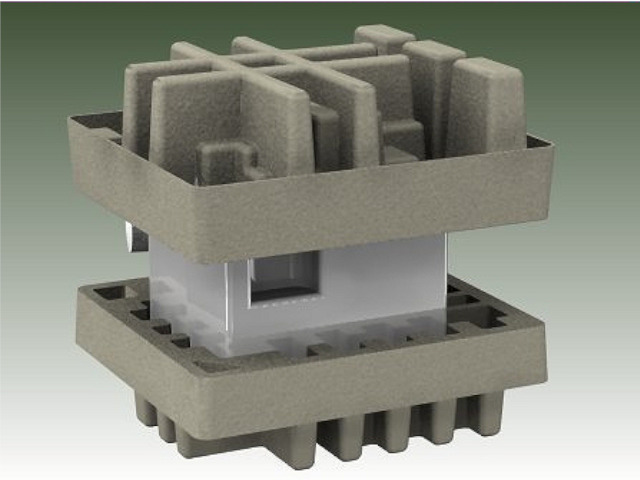

Plastic Injection molded

Steel racks and trays that are stacked on pallets or inside containers most commonly rely on injection-molded inner packaging. This material is typically used for heavy parts or in automation due to its ability to hold tight tolerances. It is also used in corrugated export packs for engines and transmissions..

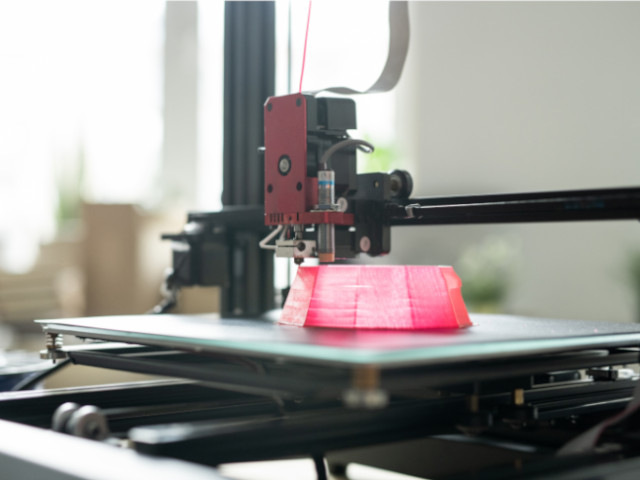

3D Printed Plastic

3D printing offers flexibility in material options and design, allowing for custom-fit inner packaging that can be quickly prototyped and produced. This makes 3D-printed plastics a viable, cost-effective and more rapid alternative to traditional injection molded or vacuum-formed plastic inner packaging.

Foams – PE, PU & X-Link

Foam, specifically Polyethylene (PE), Polyurethane (PU), and Cross-Linked Polyethylene (X-Link), are commonly used as inner packaging materials for their cushioning, shock absorption, and protective properties. These materials are lightweight, resilient and moisture-resistant; helping to prevent product damage during shipping and storage.

Vinyl

Vinyl is used as inner packaging material, particularly in the form of vinyl airbags. Vinyl airbags are reusable and provide cushioning and space-filling for various loads, especially those needing protection from moisture or requiring flexibility to accommodate irregular shapes.

Sleeve Packs

Sleeved packs are reusable bulk containers designed for transporting and storing goods. They consist of a base pallet, a durable plastic sleeve, and a lid, allowing for efficient loading, unloading, and stacking. These packs are also space-saving and can be collapsed for easier storage and return transportation.

Corrugated

Corrugated paper, commonly known as cardboard, is a popular and effective inner packaging material. It provides a cost-effective and environmentally friendly way to protect goods during shipping. The unique structure of corrugated, with its fluted middle layer between two flat liner boards, offers strength, cushioning, and easy customization.

Molded Pulp

Molded pulp is packaging that is typically made of recycled paperboard and/or newsprint. It is used as protective packaging for food service trays, beverage carriers, end caps, trays, plates, bowls and clamshell containers. Pulp products generally have a wall thickness of 3/16″ to 1/2″ and is an economical solution to expanded polystyrene (EPS), vacuumed formed PET, PVC and foams.

Plastic Corrugated

Corrugated plastic is a commonly used inner packaging material due to its durability, versatility, and customizability. It’s lightweight, moisture-resistant, and can be easily shaped, cut, and folded to fit specific needs.

Find out how SPG can help your business. Contact one of our packaging experts today!