Materials

SPG offers the most complete line of custom packaging products and solutions, creating one streamlined customer experience. Our packaging solutions are all designed to maximize performance and minimize cost. We have refined our production process to help reduce our global footprint; reducing our reliance on natural resources and our greenhouse emissions.

Below are some of SPG’s material solutions:

Corrugated

Corrugated cardboard is a widely used packaging material due to its strength, affordability, and environmental benefits. It’s made by sandwiching a fluted (wavy) layer between two flat layers of paperboard, creating a sturdy and durable material that offers cushioning and protection for products. The most common fluting types are A, B, C, E, or F. These categories determine the sizing of the flutes, which is defined by the height and frequency of the flutes.

Chipboard

Chipboard is a durable, eco-friendly packaging material made from wood pulp, offering a sturdy and cost-effective alternative to corrugated cardboard. It’s used for a variety of applications, including retail packaging, small consumer goods, and protective inserts for items like photos and artwork.

Steel

Steel is a strong, versatile material that can be used for a variety of packaging applications, including the food and beverage, automotive, and industrial industries. Steel packaging is popular for its durability, recyclability, and ability to protect contents against damage from light, air, and moisture.

Wood

Wood offers numerous benefits for protecting and transporting goods. It’s known for its strength, durability, and ability to be customized, making it suitable for a variety of applications, including shipping crates, pallets, and boxes. Wood packaging can be particularly advantageous for heavier items and when moisture protection is needed. Additionally, wood is biodegradable and recyclable, making it an environmentally friendly packaging option.

Plastic

Plastic is often used as a packaging material due to its lightweight, durability, and cost-effectiveness. It’s highly adaptable, allowing for various shapes and designs, and can offer protective barriers for products, particularly food, extending shelf life and reducing waste.

Polyethylene

Polyethylene (PE) is a popular packaging material due to its versatility, durability, and resistance to moisture, chemicals, and impact. It’s used for flexible packaging like bags and films, as well as for containers and other packaging applications.

Volatile Corrosion Inhibitors (VCI)

Volatile Corrosion Inhibitors (VCI) are chemical compounds used in packaging materials to protect metal parts from rust and corrosion. VCI materials release volatile molecules that create a protective layer on metal surfaces, preventing contact with corrosive elements like moisture and oxygen. This method offers a cost-effective and environmentally friendly way to protect metal products during storage and shipping.

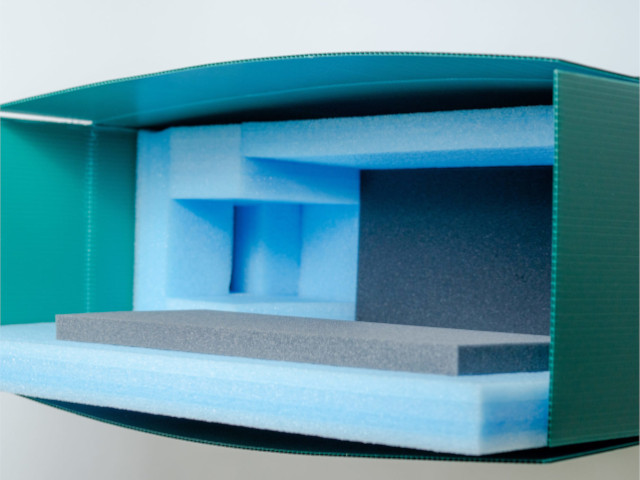

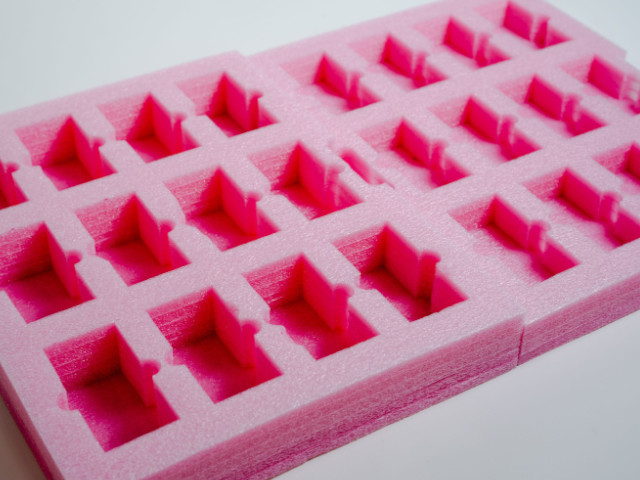

Foams – PE, PU & X-Link

Foam, specifically Polyethylene (PE), Polyurethane (PU), and Cross-Linked Polyethylene (X-Link), are used as inner packaging materials because of their cushioning, shock absorption, and protective properties. These materials are lightweight, resilient and moisture-resistant; helping to prevent product damage during shipping and storage.

Are you ready to find out more about how SPG can help your business? Get in touch with us today to talk to one of our packaging experts.